Processing and packing electronic components and assemblies using highly precise processes and methods

HTV provides several services in regards to processing electronic components:

- Packing (taping and reeling) electronic components (tray, tube and reeled goods)

- Drying electronic components to avoid component damages during the soldering process

- 3D lead inspection to exactly analyze the component’s pins

- Conditioning components, i.e., cleaning and reworking electronic components

- HTV Revivec®

- HTV-NovaTIN® (Retinning)

- HTV-NovaTIN®-PLUS

- Reballing – Refurbishing BGAs

- Mechanical processing of goods

- Shortening and/or straightening of component connections

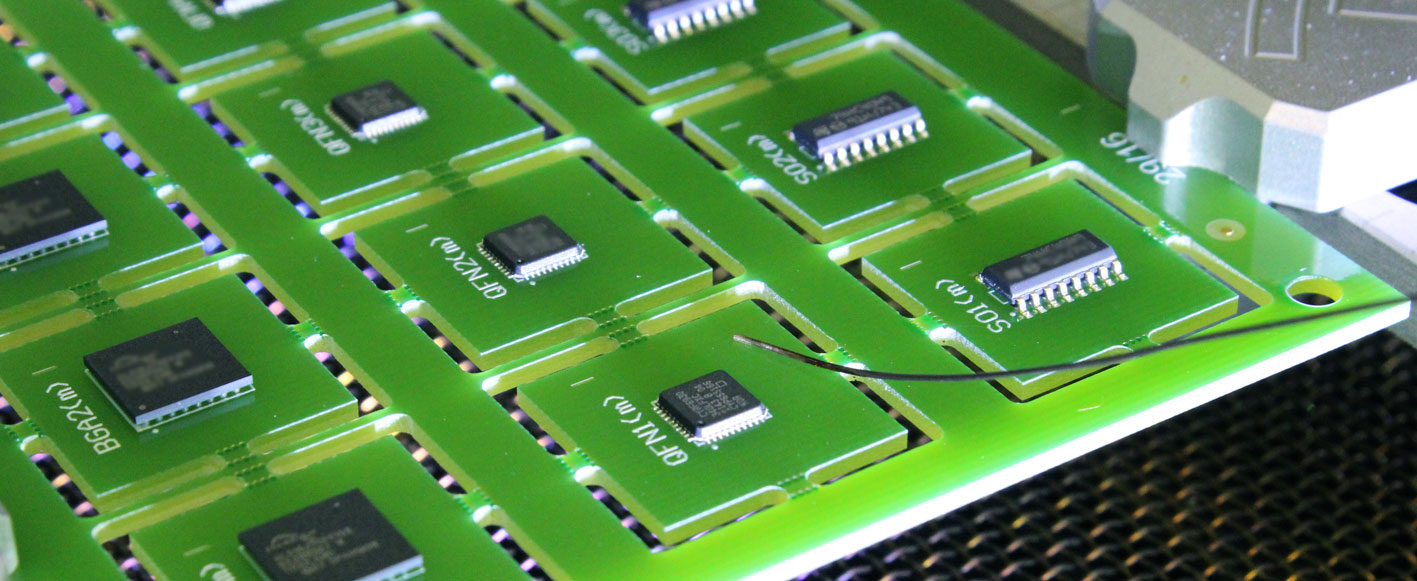

- Depaneling of printed circuit boards

- Marking/Labelling electronic components, i.e., following a programming or a testing procedure

- Removing the original component labelling to prevent illegal or unlicensed duplication of assemblies

- Reworking printed circuit boards to repair or change electronic assemblies

There are many various reasons to process electronic components and assemblies, such as a production-ready packing in regards to further processing.

Ascertaining and evaluating the current state of one’s goods is just as essential. Both quality and processability may be restored using several specific processes, if necessary.

Customer-specific markings, or, alternatively, present original markings may be removed using various laser technologies during the marking process to prevent illegal or unlicensed duplication of assemblies.

HTV’s state of the art reworking systems make it possible to remove components automatically from an assembly or mount them on a printed circuit board. Assemblies can be repaired and/or changed in accordance with the highest quality standards in the swiftest time possible.