Various marking procedures of electronic components

An overview:

- Marking using a laser

- CO2 laser

- Solid-state laser (can be used on metallic surfaces too)

- Time stamps and machine allocation data application are possible

- Marking using a label (reflow proof)

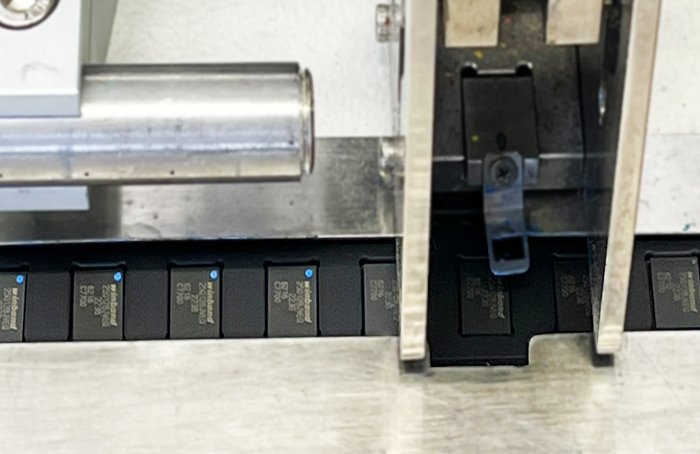

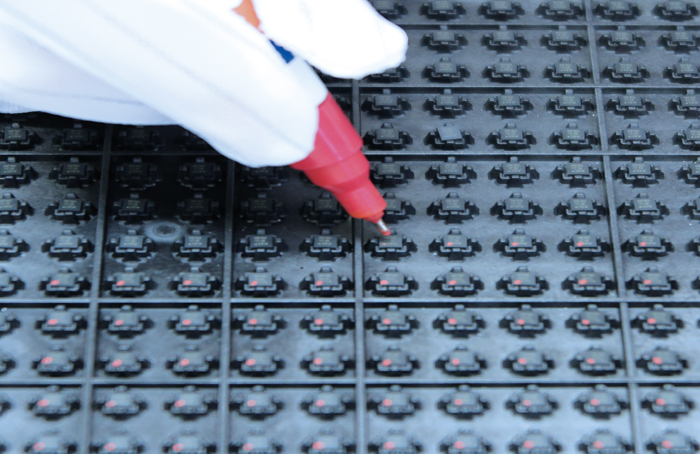

- Marking using a color dot

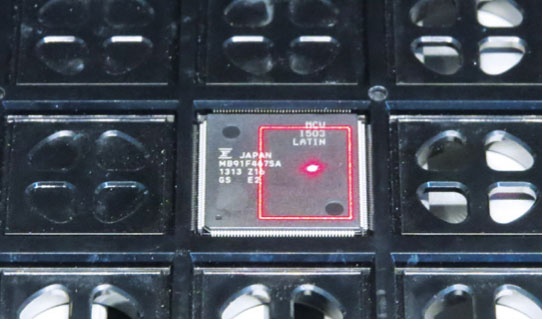

- Removing the original labelling

- This is to prevent illegal duplication

- Negative and/or inverted marking

Following a programming or an alternative processing, electronic components are then labelled or otherwise marked. A component marked with a post-processing serial number visibly shows the programmed state of said component, for example. A time-stamp or the allocation number of the testing device used on the component gives the customer important tracking data for 100 percent retraceability.

To protect classified company expertise it is in some cases necessary to render the original manufacturer’s labelling illegible. Using a special procedure developed by HTV the present labelling can be removed and the component be marked, if required, with a new customer specific label. HTV possesses several different laser technologies allowing for marking almost any kind of component surface, specifically including metallic surfaces, with precise and high-resolution labels, even with data matrix code among other things.