Applied standards

- ECSS-Q-ST-60-14C

Relifing of EEE components in accordance with ECSS-Q-ST-60-14C

Relifing is an important part of our long-term storage services.

It is of vital and central importance for aerospace projects. These projects require electric, electronic and electromechanical (EEE) components, which have to be maintained and kept in close-to-pristine condition for years. Only relifing can maintain the reliability of electronic components across the entire storage timespan.

Why is Relifing important?

Aerospatial EEE components are not just meant to conform to strict project timetables but also economical restrictions in regard to their acquisition. This usually requires a long-term storage for later use in order to avoid obsolescence problems and secure strategic stocks. With our relifing process we can surveil and ensure that your components are ready to use for your areospace project even after a longer storage period, making it a proactive move in obsolescence management.

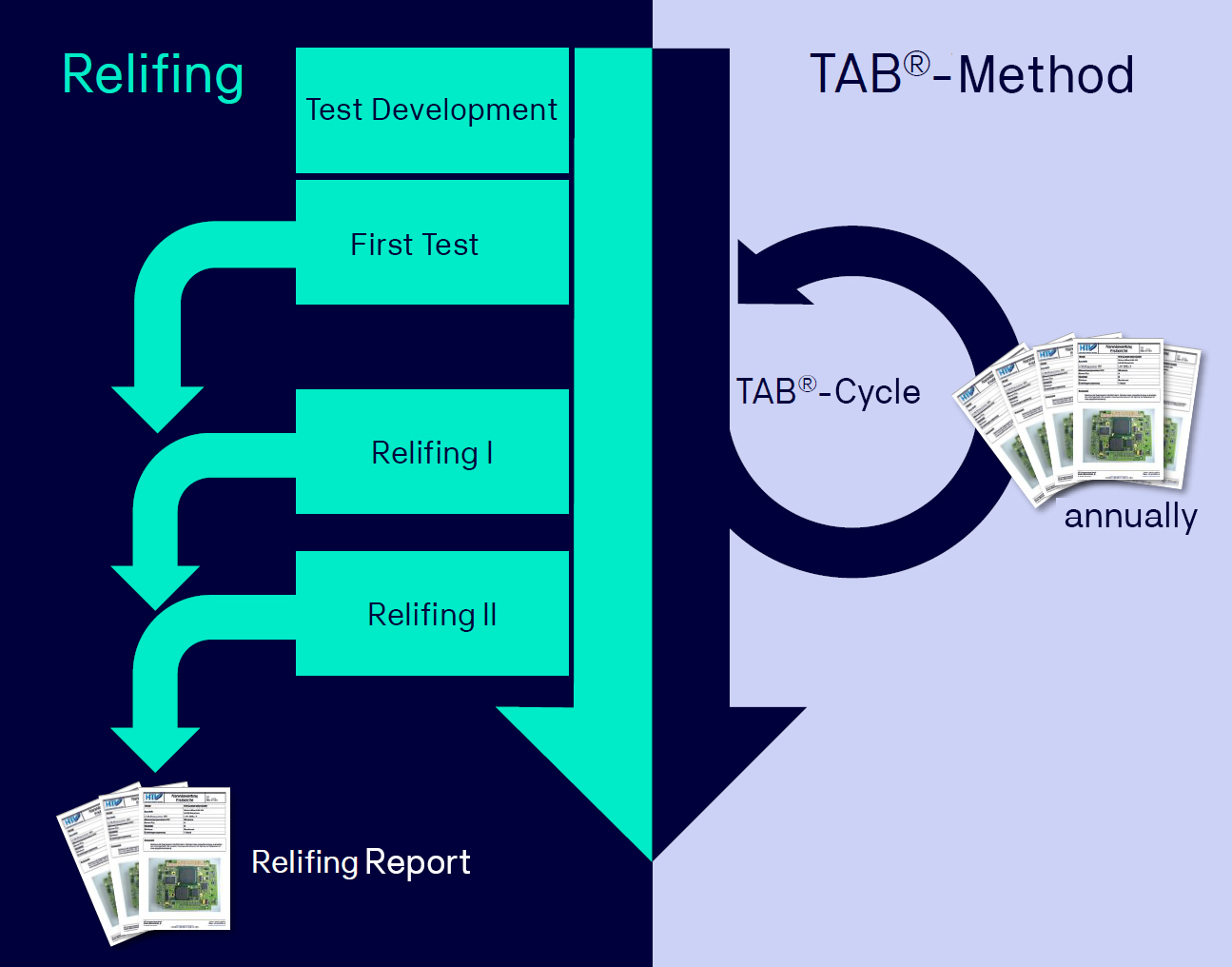

Our relifing process

Adverse storage conditions or merely unsuitable handling can degrade or simply cause premature aging in EEE components during storage, which ultimately makes their usage in an aerospace project a liability. Our relifing process means to identify any change in a component which could impact its processability and efficiency. This is all done in accordance with the european ESCC standard ECSS-Q-ST-60-14C, which defines the requirements and steps necessary for the relifing process. The optimal test sequence consist of:

- Visual inspection: Using magnification, the components are examined corrosion, general material degredation or other defects

- Electrical testing: The components are examined for the fuctionality

- Leak test: If necessary, the components are examined for leaks

- Specific tests: Additional tests, if required, i.e., the solderability test to confirm the components’ processability

Relifing is a quality control procedure, during which electronic components for aerospatial applications are stored according to a plan, repeatedly tested and taken from storage in controlled conditions. Said conditions are provided in the most optimal fashion by ALTER | HTV’s TAB® long-term storage.

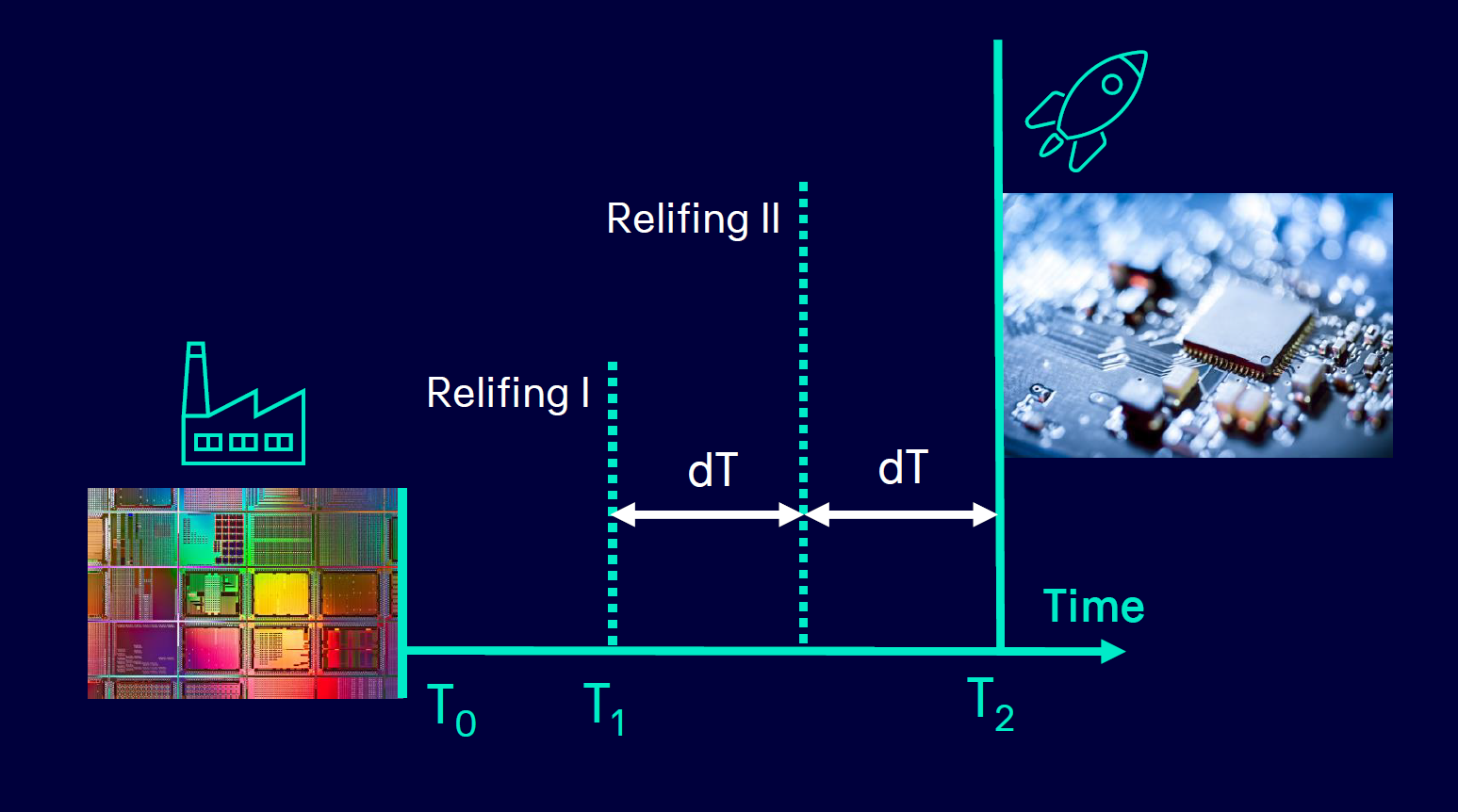

Relifing’s temporal framework

- T0: Time of manufacture of the EEE component (original date code)

- T1: Maximum storage time without relifing (7 years)

- T2: Maximum storage time between manufacture and installation (15 years)

- dT: Maximum storage time after a relifing process, which can be repeated one time only (after max. 4 years)

Relifing report

After the end of any relifing cycle you’ll receive a comprehensive report containing the following information:

- Details regarding the component and lot/batch

- Information regarding the tests which were performed

- Test results

- Evaluation (pass/fail)

- Relifing date code (DC)

Find out more about our comprehensive services regarding long-term preservation and storage and how we can support your aerospace projects.

More about ALTER | HTV’s long-term storage and preservation