Globally unique HTV TAB®PLUS Long-Term Conservation for the long-term storage of electronic components for up to 50 years

Applied standards

- DIN EN 62402

- DIN EN 62435

- GEIA-STD-0003A

- JEP 160A

HTV TAB®PLUS Long-Term Conservation method (Thermal-Absorptive gas Barrier):

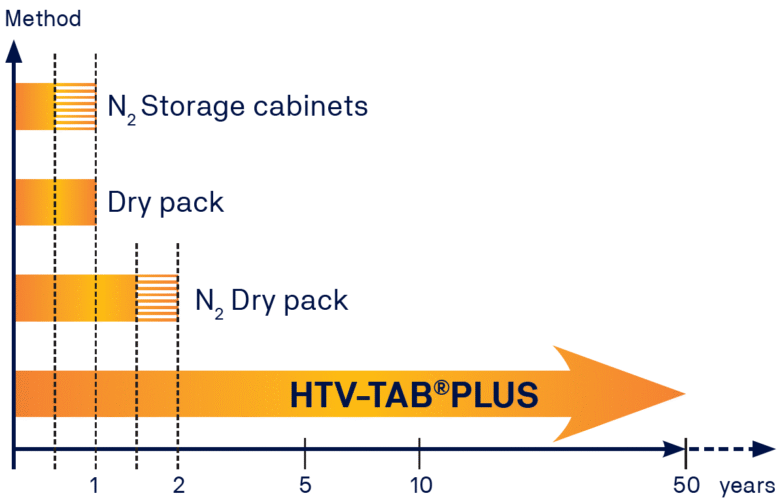

- Preservation and storage of electronic components such as components, assemblies, displays, wafers and DIEs for up to 50 years in accordance with DIN EN IEC 62435, GEIA STD-0003 and JEP 160A (and beyond)

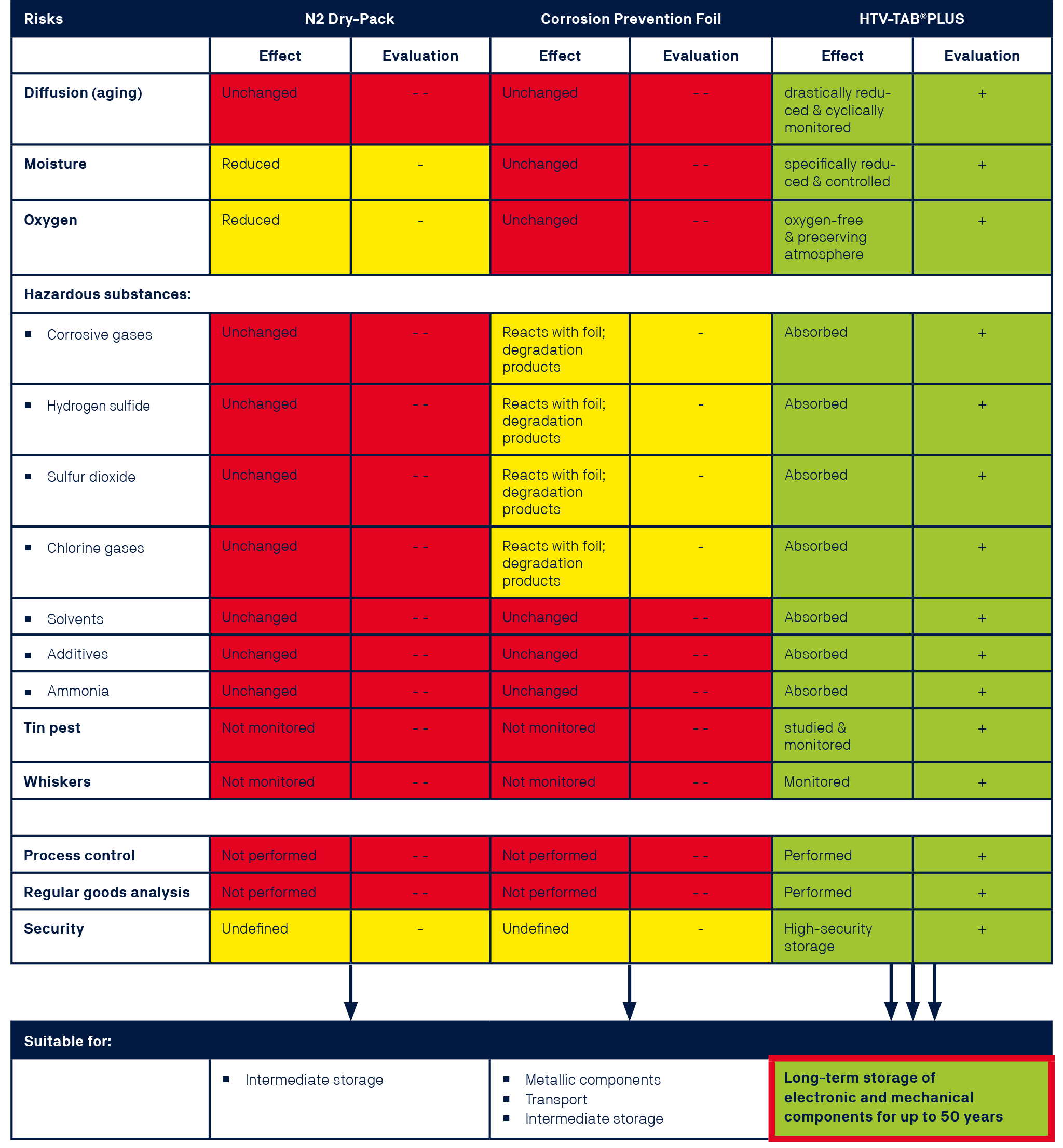

- Significant reduction of aging processes compared to conventional storage methods

(see Comparison of storage methods), e.g.:- Immense reduction of diffusion (e.g., intermetallic phase growth)

- Almost no corrosion and oxidation processes

- Prevention of whisker formation and tin pest

- Absorption of hazardous substances such as outgassing of plasticizers or

corrosive gases

- Cyclic evaluation of goods in comparison to the results of previous evaluations

- Storage in high-security facilities

- Extension of product life cycles

- Ensuring the after-sales business

The HTV TAB®PLUS Long-Term process, with decades of proven success and globally unique, enables a significant reduction of critical physical and chemical aging processes in electronic components through special absorbing materials against hazardous substances, a preserving atmosphere and specific storage conditions.

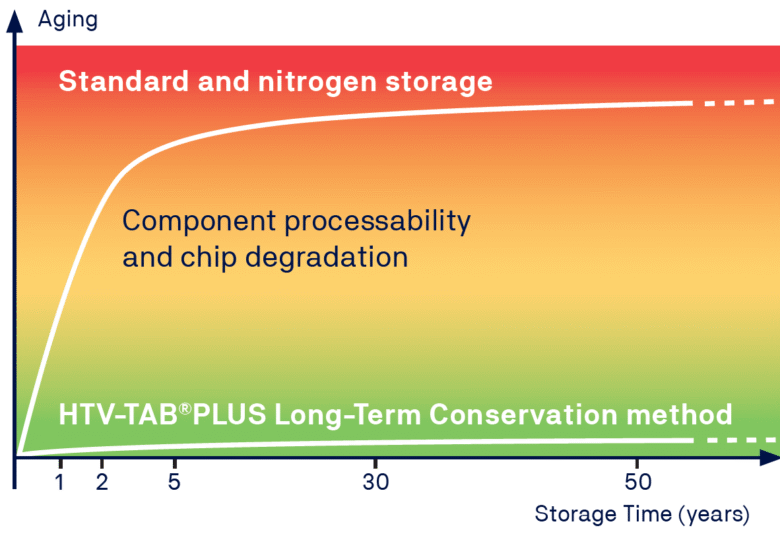

Material changes usually occur most rapidly during the first few years of standardized storage. Components not immediately required should be stored using the TAB®PLUS method as soon as possible to ensure the long-life cycle of the product.

The HTV TAB®PLUS process significantly reduces diffusion

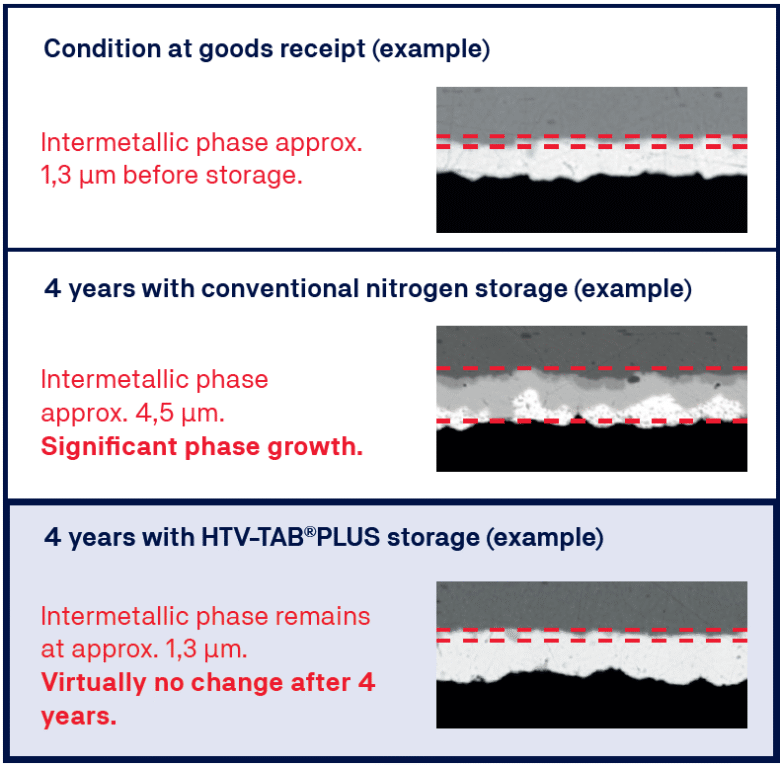

The HTV TAB®PLUS process significantly reduces diffusion, a key aging factor, by adjusting storage temperatures to increase activation energy. This approach drastically minimizes the growth of intermetallic phase (i.e., diffusion at the component contacts) between the copper from the inside of the component pin and the tin of the pin surface. HTV TAB®PLUS Long-Term Conservation also strongly reduces the aging processes inside the component, such as diffusion at the chip level. Corrosion and oxidation are almost entirely and efficiently prevented over the long term by specifically absorbing moisture, oxygen, and material-dependent hazardous substances. The risk of whiskers (tiny single crystal needles that can grow from the material and cause short circuits on printed circuit boards or individual components) and tin pest is also rendered negligible.

Components are packed/wrapped in several layers of various special functional foils developed by HTV, which effectively block foreign substances and absorb a wide range of hazardous materials.

As a sophisticated combination of different methods HTV TAB®PLUS Long-Term Conservation minimizes nearly all relevant aging factors.

Depending on their initial condition, electronic components can be preserved for up to 50 years. This guarantees/ensures the quality, processability and functionality of components, maintaining the availability of spare parts for several decades. With strategic obsolescence management, the impact of component discontinuations is mitigated, allowing components purchased during end-of-sale or last-time-buy to be stored as a long-term strategic reserve.

Storability according to the storage method

Effectiveness of HTV TAB®PLUS Long-Term Conservation compared to conventional nitrogen storage

A key indicator of harmful aging processes is the growth of the intermetallic phase, such as between the outer tin coating and the base material of the contact pins: The direct comparison of components stored using N2-drypacking versus TAB® shows clear differences in the growth of the intermetallic phase under SEM-EDX examination. Conventional nitrogen storage shows an increase in the intermetallic phase of approximately 1 μm per year, whereas HTV TAB®PLUS long-term storage exhibits almost no phase growth.

HTV TAB®PLUS long-term storage exhibits almost no phase growth. In regular nitrogen storage, the intermetallic phase grows by about 1 μm each year. However, components stored using HTV TAB®PLUS show almost no growth.

Almost no phase growth

using HTV TAB®PLUS Long-Term storage!

Prior to storage, a thorough examination and assessment of the components establishes the foundation for using the HTV TAB®PLUS Long Term Conservation. The components’ current aging condition, any pre-existing hazardous substances and risks are identified using advanced analytical techniques. This determines the necessary parameters required for effective long-term preservation.

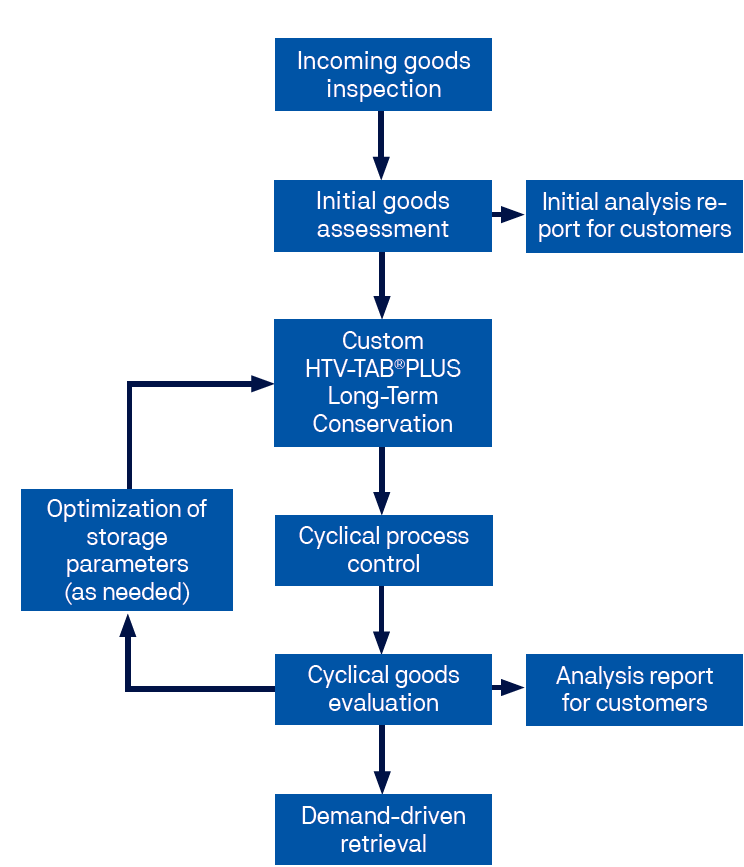

Process diagram of the HTV-TAB®PLUS Long-Term Conservation

Process monitoring and periodic product evaluation of the stored components, along with continuous optimization of storage parameters and regular analysis reports, guarantee the highest quality and transparency throughout the storage process. All data and analysis reports are archived at least 15 years after the delivery of goods to the client, ensuring complete traceability well beyond the storage period.

Comparison of storage methods