HTV – your experienced partner for qualified research projects regarding electronic components and assemblies

Decades of experience, state of the art equipment, specifically assembled teams of highly certified engineers, technicians, chemists, phyisicists and material scientists, as well as close collaboration with field-leading universities and research institutions all over the world. Working together in a consortium of various project partners makes it possible for us to actualize a wide range of different yet innovative reasearch projects in a targeted manner for customers, institutes and official authorities based on the latest science.

HTV’s research services

IT and hardware security

Microelectronics/Medical Technology

Resource efficiency

Individual research projects

We actualize your individual research projects as a competent partner in almost all areas of electronics and material science.

From the application for being funded by research supporting institutions (reseach objective, work programm, time and financial plan) through project management and independent survey or market analyses, all the way up to patent research and all the associated publications; be it the reseach of new hardware, software, IPs (interlectual properties) or other questions in the field of matieral science – we can implement the right research work for nearly every customer request.

Feel free to inquire.

For your convenience, an overview of HTV’s research projects:

IT and hardware security

Data security, counterfeiting protection and defence against cyber and hardware attacks is of vital importance for high-income countries. HTV can support you to both protect and research protection features for your hardware. Furthermore, we can advise you in regards to security and component counterfeiting or manipulation.

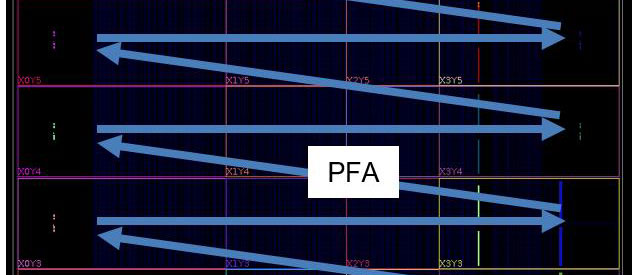

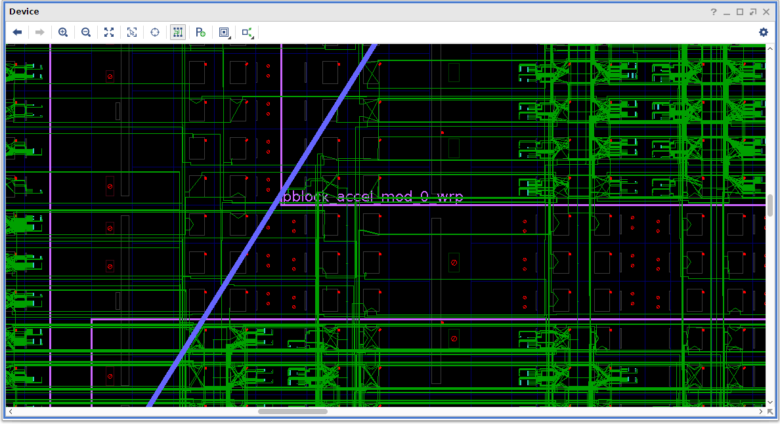

Further development and research of (SoC) FPGA technology

Several years of research as part of various studies of FPGA technology. Among other things we tested the abilities and properties of the latest chip technologies in practice and showed their feasibility limits. This fundamental and in some aspects groundbreaking research will result in a large number of new possible uses and applications in the future, specifically in regards to IT security and functional security, such as analyzing the bit stream of FPGAs which make it possible to predict how FPGA design may influence their function during operation, or research projects that visualize side channel attacks and how they may easily be used to access a chip’s inner processes (like its secret key) through its power consumption or electromagnetic emissions.

Publications (mostly in German)

An Isolated Partial Reconfiguration Design Flow for Xilinx FPGAs

Federal research project ‘Trustworthy electronics’

Preventing attacks on electronic systems by using innovative multi-sensor technology (VE-SAFE)

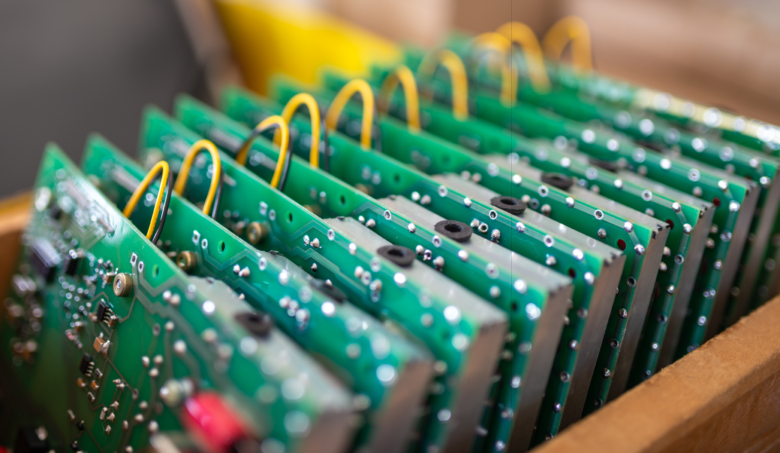

In a joint project with the federal ministry for education and research (BMBF, “Bundesministerium für Bildung und Forschung”) HTV was tasked with developing surveillance electronics, which is to be moulded together with until now unprotected customer electronics on a printed circuit board to detect possible attacks on the hardware (the customer electronics) of the electronic device in question and execute appropriate countermeasures. The developments in this research project will enable manufacturers of electronic devices to conveniently and cost-effectively increase the security level of their electronic assemblies in the area of hardware security in the future.

See also these HTV-News: Federal research project ‘Trustworthy electronics’

Publications (German)

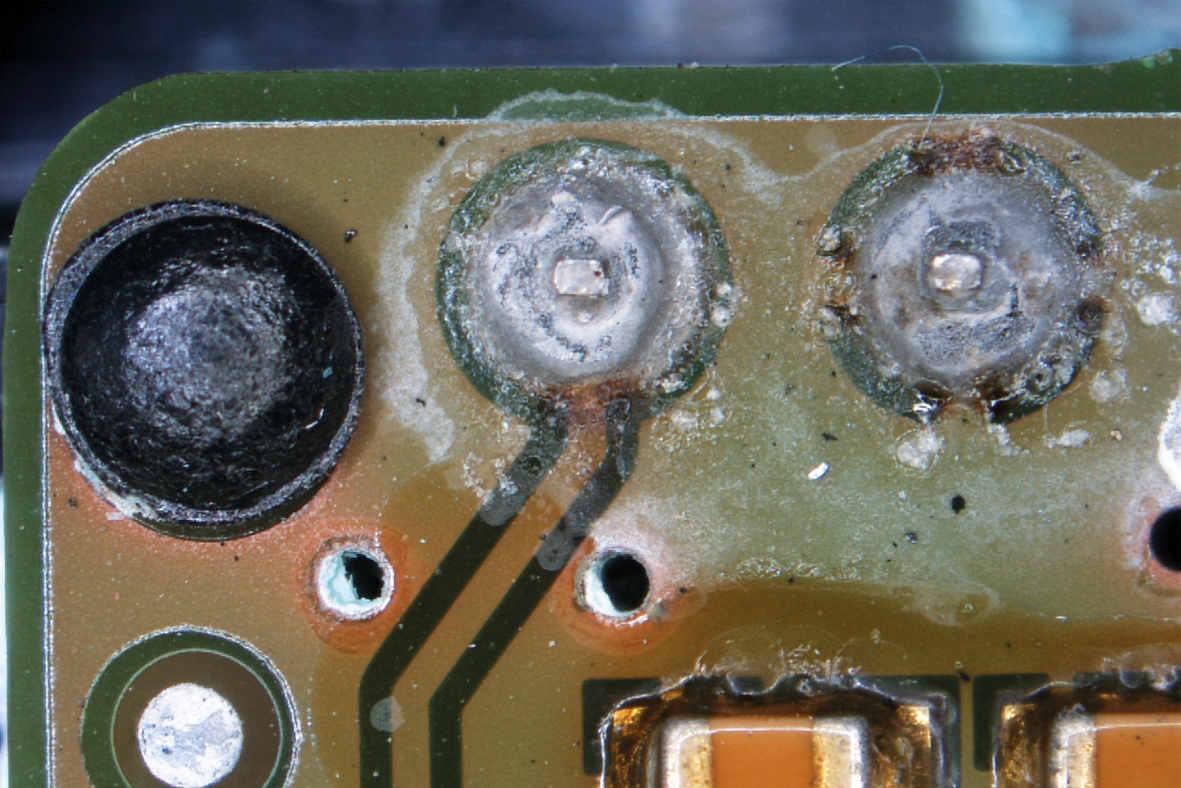

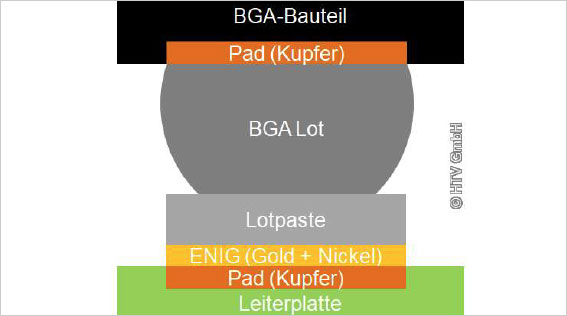

Research project “Recognizing hardware manipulation/rework via solder analysis”

An electronic assembly’s IT security does not just depend on its software but largely its hardware as well. Should an assailant be able to secretly manipulate the hardware before delivery, he can thus gain an unnoticed and permanent access to the assembly’s internal processes.

Together with the federal bureau for information technology security (“Bundesamt für Sicherheit in der Informationstechnik” or BSI) HTV researches in various studies which differences show up in manipulated or otherwise reworked assemblies, which analysis methods may be used to ascertain this and which methods mayn show the best test results.

Publications (German)

Ressource efficiency – Researching the aging processes of materials and assemblies

One of many HTV specialties are long-term research projects with international partners regarding aging and storage of electronic components. HTV’s very own propriatary developed TAB® long-term conservation and storage method forms the basis for this, as a continuous research in regards to the aging processes of various components and recent materials is necessary to provide adapted long-term storage for new components, assemblies and other products.

Evaluation and optimization of the long-term durability of digital storage media (Labest Digital)

The Labest Digital research project, in collaboration with ALTER | HTV, is investigating the long-term durability of digital storage media. The focus is on the durability and reliability of data carriers such as DVD, SSD, HDD, microfilm, M-Disc and NanoFiche under various environmental influences. The aim of the project is to develop a differentiated preservation concept that ensures the long-term preservation of digital information.

The final report is expected in 2026.

Read more about the Base research project here:

HTV research project regarding the long-term storage of OLED displays

OLED displays are seeing an increasing usage in smartphones and TV screens as well as in the automotive industry – HTV supports this development through reseach projects regarding, among other things, the long-term storage of OLEDs. The research and ascertainment of optical parameters is of vital importance, especially in medical technology, which requires the optical parameters of the LEDs used to remain constant across their entire life-cycle.

See also:

HTV News: HTV research project regarding the long-term storage of OLED displays

HTV Services: HTV light laboratory – testing optical parameters

Publications (some in German)

Research project: Long-term availability of electronic and electromechanic control units

Because of their complex compositions, which usually contain various new materials, electronic and electromechanic control units differ greatly from more common electronic components. Until now there didn’t exist any appropriate processes for the long-term storage of control units. In this project several methods (optical, mechanical, electronical) to evaluate aging processes in control units were developed and those control units were specifically aged to ascertain age related changes using said developed methods. This made it possible to identify storage-critical factors and, using those factors as a foundation, to develop methods for the long-term storage of control units. HTV uses these methods for an appropriate long-term storage via the TAB® long-term conservation. The state of the control units is frequently monitored before and during storage using those methods, which ensures replacement component availability for several decades as well as a significant increase of the service life of devices and machines.

Publications(German)

Ressource efficiency: long-term availability of electronic/electromechanical control units;

Research objective: Development of a storage process for the long-term conservation of electronic/electromechnical control units

Report/Electronic source: Halbleiter-Test & Vertriebs-GmbH

Ressource efficiency: long-term availability of electronic/electromechanical control units

Report: “Fraunhofer-Institut für Betriebsfestigkeit und Systemzuverlässigkeit” meaning the Fraunhofer Instutite for Structural Durability and System Reliability

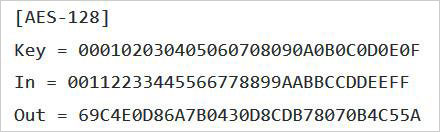

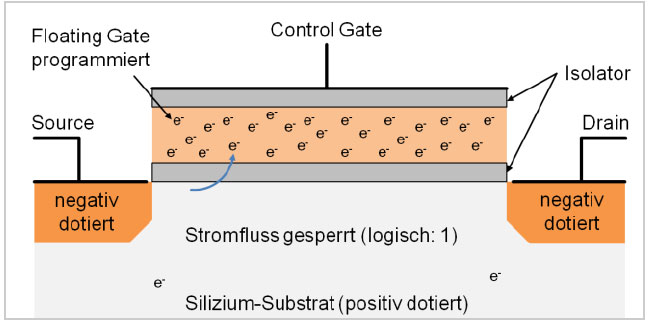

Research project: Memory qualification – data security in flash memories

Electronics in use all around the world are undergoing massive change, which especially affects memory components. Current developments regarding digital memory components are aiming to increase their speed and data transfer rate as well as lower their energy consumption while at the same time raise the amount of data stored per area unit more and more.

A memory qualification analyzes the data security in electronic flash memories (such as NAND and NOR). The qualification process is as follows: individual memory areas are aged, then programmed with test data, then the components are stored at high temperatures, finally the memories are read out and possibly appearing bitflips are analyzed. Knowing the quality and/or lifespan of the employed memory technology is of vital importance for later applications to ensure a reliable operation across the product’s entire length of life.

An HTV memory qualifcation ascertains the quality of many varied memory technolgies, by which the most appropriate technology may be chosen for the respective application to ensure a most satisfying amount of data security for the entire operation of the corresponding assembly.

Publications(German)

Research project: Characterization and analysis of the aging processes of LC modules

Many products of the electronics industry have built-in LCDs (liquid crystal displays), which are used to represent various kinds of information. Especially the automotive as well as the aerospacial industry, which historically also used analogue display elements, underwent a continuous technological transformation in recent years. The number of LCDs built into cars and airplanes rises steadily, likewise the size of those modules increases from year to year.

Long-term storage of LCDs is subject to enormous difficulties, owing to their rather complex composition of mulitple materials. For this reason HTV researched the aging processes of liquid crystal displays to be able to better adapt and validate the globally unique long-term conservation process TAB® for the storage of displays.

Publications(German)

Characterization and analysis of the aging processes of LC modules

Aerospace

The aeroespacial industry has extremely high demands regarding the security, quality and reliability of th components and materials it employs. For example, a satellite in orbit has to function flawlessly for more than ten years without the possibility of a repair. For this reason the aeroespacial industry follows especially strict rules and guidelines in regards to qualifying individual components.

HTV supports both stately as well as commercial space flight projects with its very well equipped analysis departments and appropriate specialized knowledge regarding the aeroespacial industry.

LEAD-FREE TRANSITION FOR THE EUROPEAN SPACE SECTOR

Due to the overall transition of the Electronics industry worldwide to a Pb-free realm, the Space Industry is more and more confronted with a situation where they cannot avoid using EEE (Electrical, Electronic and Electromechanical) parts with Lead-free finishes and they need to manage the associated risks. The growing use of commercial components (COTS), notably for the expanding market sector of constellations, means that European Space Industry is already using large amount of components with lead-free finishes even when the equivalent leaded high-reliable version is available. Even though the Space Sector is exempted from RoHS restrictions (Restriction on the use of certain Hazardous Substances), market pressure may also result on potential future difficult availability of leaded solder paste.

This project addresses the main challenges of the Pb-free transition for the European Space Sector that were described in the Roadmap delivered in 2020 by the ESCC Task Force created to that end. First, the obstacles that hinder today the wider use of COTS components in space projects are studied, using existing qualified assembly processes based on leaded solders. Second, a comprehensive evaluation of two lead-free solders is launched that show promise for the Space Sector including reliability model development.

Sn-solders were alloyed with lead at the beginning of the electronics era mainly to inhibit the growth of whiskers, therefore going to lead-free electronics creates a serious risk for space projects that may result in catastrophic failure in the satellite due to whiskers growth. The Space sector has developed mitigation approaches but the real challenge is to obtain accelerated tests that will give confidence that, for a given mitigation used and for the duration of the project, the risk is managed and acceptable. For that, basic research is performed to advance the state-of-the-art on the knowledge of whisker growth, leading to the determination of the pertinent activation energies that can be used in the design of accelerated tests.

HTV contributes to the LETTERSS project with its comprehensive analytical methods ranging from X-ray examinations, light microscopy, XRF, Nanoindentation, microsection analyses to SEM-analysis. Further, HTV plays an important role in the literature research and also prepares a survey to determine the state of the art in soldering alloys in the space industry. In addition, the solder joints of half of the test vehicles are be examined in HTV’s laboratories using the above-mentioned analytical methods. In addition, the test vehicles are thermally cycled and electrically monitored during cycling in HTV´s laboratories. The failure analysis after thermal testing is also carried out at HTV. In WP5, HTV leads the work closely with TU-DA and participates in research on whisker formation. The various facilities at HTV are also used here to develop an accelerated whisker test. In addition, HTV scientists are involved in the preparation of reports, literature research, as well as presenting results at conferences.

Further information on the project can be found on the official LETTERSS homepage at www.letterssproject.eu.

Evaluating the state of EEE components in Germany

Electrical, electronic and electromechanical (EEE) components are required to a considerable extent in space flight systems and satellites. Automotive components are used as standard in the automotive industry. HTV evaluated space flight qualified EEE components on behalf of the DLR (“Deutsches Zentrum für Luft- und Raumfahrt e. V.”, meaning the German Aerospace Center). The DLR space agency coordinates and represents the interests of German space flight end users and manufacturers in the ESSC system (European Space Components Coordination), organizing the strategies for effective use of EEE components and technologies in arrangement with the aeroespacial industry.

Publications(German)

Evaluating the state of EEE components in Germany

Researching alternative testing methods for COTS (ATCOS)

The usage of commercial off-the-shelf (COTS) components by the European aerospace industry is gaining momentum and traction. Onboard or unit level testing is increasingly suggested instead of the more common component level standard. While this may be useful and cost-efficient it presents the aerospace industry with the difficulty of gathering a satisfying amount of information regarding the effectiveness of the final testing system, as well as the reliability of commercial off-the-shelf components used in space flight.

The aim of this research project on behalf of the European Space Agency (ESA) is to gather further information regarding the actual performance and reliability of commercial off-the-shelf electronic components, with a special emphasis on components used in the automotive industry (certified in accordance with AEC-Q100). In particular, the effectiveness and suitability of testing electronic assemblies in comparison to individual electronic components (EEE components) will be examined, also accelerated testing procedures will be used (such as the Highly Accelerated Stress Screening (HASS) and the Highly Accelerated Life Test (HALT)). The samples produced in the reasearch project will then be analyzed in regards to reliability, early failures and radiation hardness, using specific analysis plans. The research project collects and analyzes huge amounts of test data and information regarding the retracability of commercial off-the-shelf components (EEE components).

Publications(German)

Researching alternative testing methods for COTS (ATCOS)

Micro electronics and medical technology – building prototypes and surveying feasibilities

Do you require expertise developing hardware, samples and prototypes? HTV can help you make your hardware and software projects a tactile reality, using our own research projects, in-house tool development, knowledge gained from failure analyses for customers as well as employees with decades of experience in the areas of circuit development, layout creation and assembly development.

By customer request HTV develops prototypes and simulations to visualize the functions of wildly varying technologies. FPGA technology is very often used for rapid prototyping to simulate electrical circuits or algorithms. This way it can be ascertained very swiftly whether the chosen technology is appropriate for the planned usage.

Development of a textile sensor for healthcare beds

Outpatient geriatric and nursing staff face very particular challenges in providing high quality care while being understaffed and under high physical and psychological stress. Several different companies are developing care supporting technologies, yet is not easy to directly address the care staff’s actual needs.

New user-friendly solutions are being developed in the “DigiKomp-Ambulant”, meaning DigiKomp outpatient research project, in close cooperation with developers and end-users. The starting point is the development of a new sensor system which gathers the data of those in need of care, data which they themselves, their relatives, the nursing staff and the supervising doctors judge as essential (such as vitals or movement data). New networking software for mobile devices forms the basis for making these informations accessible to, among others, nursing staff, even when they are not present on site. This way the outpatient emergency services can acquire the necessary skills to deal confidently with humans and technology: they are better prepared, can carry out their tasks with more focus, and they are always in contact with everyone involved. This also leaves more time for communication and relationship formation through personal discourse. This research and development project was funded by the federal ministry of education and research (“Bundesministerium für Bildung und Forschung” or BMBF) as well as the European social fund (“Europäischer Sozialfonds” or ESF) as part of the “Future of Work” program.