Testing and selecting components according to datasheets or customer specifications

Applied standards

- AS6081

Our services:

- Extensive testing capabilities

- Datasheet-based testing

- Customized component testing

- Wafer testing

- Authenticity testing and programming

- Component selection according to customer specification

- In-house test software development

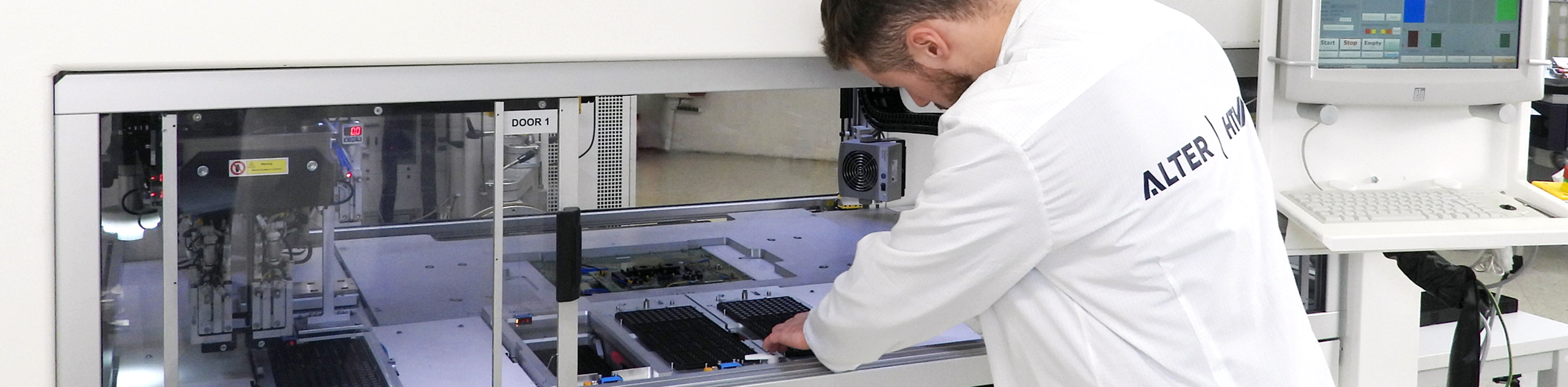

High-Precision component testing at ALTER | HTV

At ALTER | HTV, we offer comprehensive component testing that can be tailored to both datasheet specifications and individual customer requirements. Our state-of-the-art large-scale testing systems and specially developed testing applications ensure the electrical functionality of electronic components and assemblies, whether they are digital, analog, or mixed signal.

Extensive testing capabilities

Our diverse measurement and testing systems enable a thorough examination of individual components such as ICs, ASICs, transistors, and operational amplifiers, as well as complex sensors, displays, and entire assemblies. Additionally, we conduct functional tests of electronic components under high voltage or high current conditions.

Datasheet-based testing

As part of our datasheet testing service, we assess a wide range of parameters under various temperature conditions (ambient, high, or low temperatures, ranging from -60°C to +150°C). These tests are crucial for ensuring the quality and authenticity of components, especially those of uncertain origin, as they provide an initial assessment of the component’s authenticity without further analyses (such as X-ray analysis or wipe tests).

Customized component testing

For requirements that go beyond standard datasheet specifications, we provide customized component testing tailored to customer needs. This involves testing components under specific conditions defined by the customer, such as temperature, voltage, and electrical characteristics, to ensure they meet the customer’s unique operational needs.

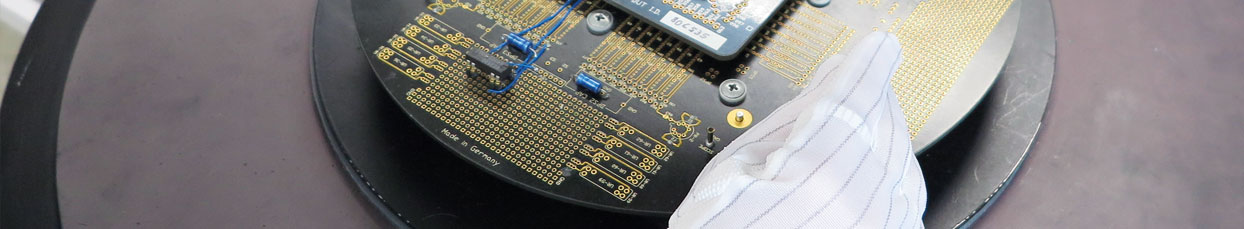

Wafer testing

We conduct component tests directly on the wafer, even under high-temperature conditions, to promote cost-effective processing and early identification of defective dies. This process includes creating an electronic wafer map during testing to mark defective dies for easier sorting later.

Authenticity testing and programming

We use blank checks to verify the memory of programmable components, ensuring that the chip’s memory area is empty. Our testing through programming allows for a quick and secure verification of the components’ responsiveness and memory integrity.

Component selection according to customer specifications

Our selection procedures sort components based on customer-specific electrical parameters. This enables precise classification into selection categories, such as categorizing LEDs by color temperature to avoid color deviations during usage.

In-house test software development

ALTER | HTV excels in crafting bespoke in-house test software, ensuring precision and adaptability for all electronic components. Our cutting-edge solutions guarantee unmatched reliability and performance tailored to your needs.

Conclusion:

At ALTER | HTV, we offer you both standard and customized solutions for component testing and selection, ensuring they meet the highest quality standards.

Eager to learn more about our services? Don’t hesitate! Reach out to us anytime using our contact form or connect directly with our sales team. We are ready and committed to fulfilling your specific requirements.