Evaluation of the reliability of assemblies, devices and systems

Applied standards

- SN29500

- MIL-HDBK-217 FN2

- ANSI/VITA 51.1

- Telcordia Issue 4

- 217Plus:2015/Notice 1

- Chinese GJB/z 299C

Areas of application:

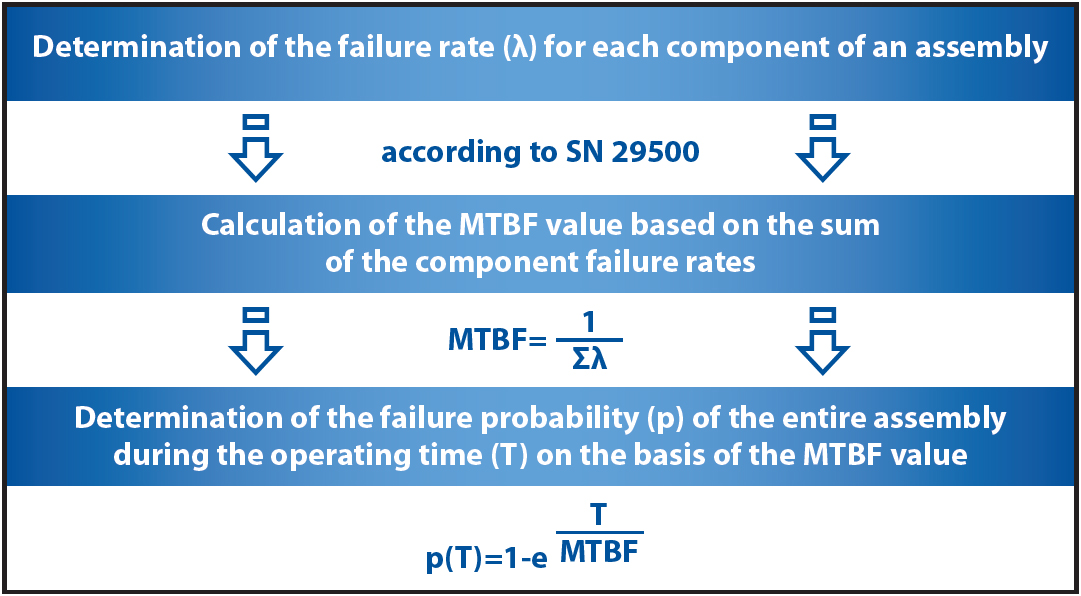

- Calculation of an assembly’s MTBF (Mean Time Between Failures)

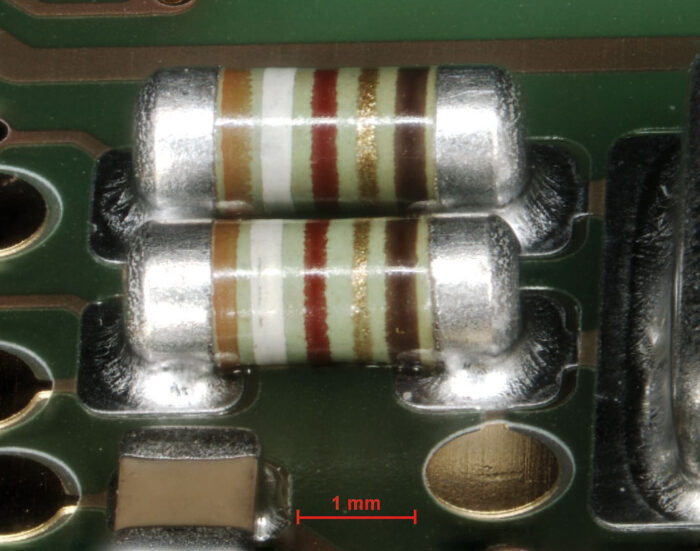

- Determination of underlying failure rates and failure probabilities of individual components

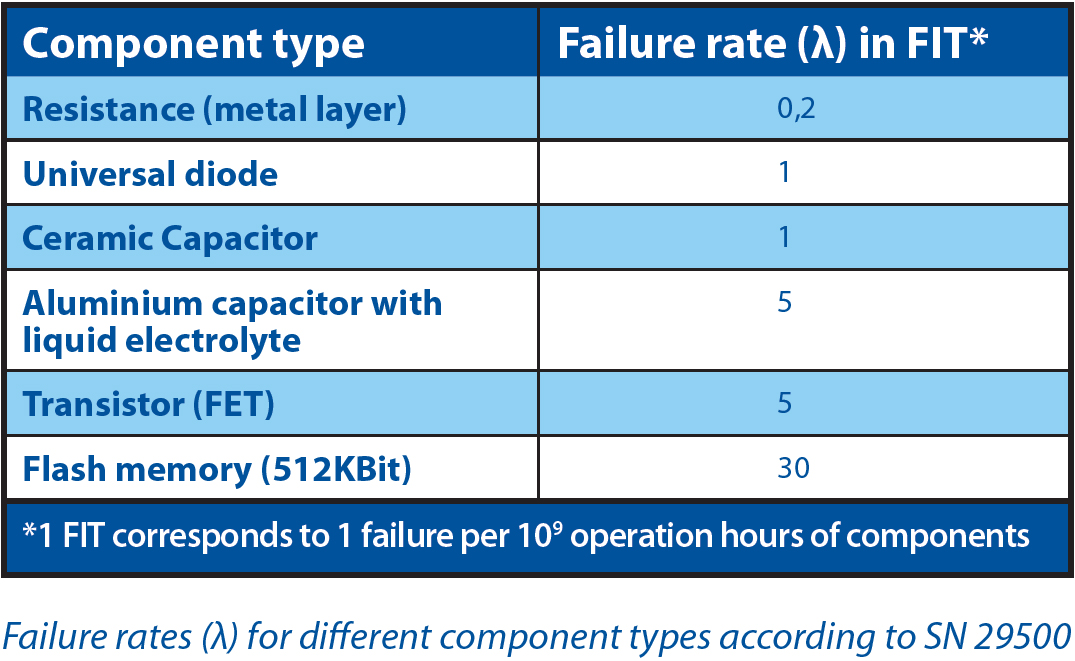

The MTBF is the expected length of an average operating time between two sequential failures and is used for units to be repaired (assemblies, devices and systems) as a parameter of reliability. A higher MTBF means a more reliable device. The underlying failure rates of technical components used in calculating the MTBF, especially in regards electronic components, may vary highly depending on the individual component type, and are expressed in FIT (Failure in Time). A higher FIT equals a statistically higher failure rate of components.

Using a customer’s provided bill of materials (BOM) and pre-defined environmental conditions HTV can determine an individual component’s FIT. Under the assumption that the failure of a single component will cause the entire device to fail, the sum of all the components’ failure rates represents the failure rate of the entire device. Thus, HTV may already calculate or estimate and compare the probability of failure of complex devices during the construction or even during the planning phase. This can provide valuable insight into a device’s service life cycle, even in regards to warranty issues.